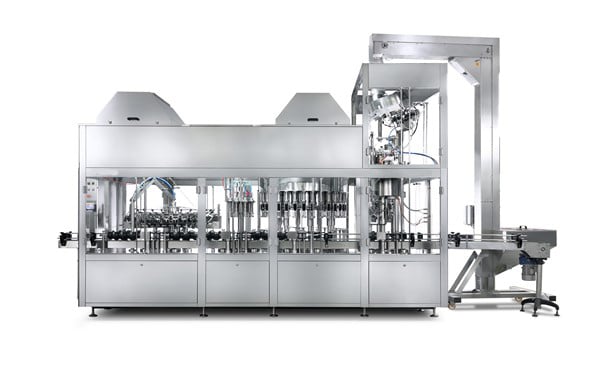

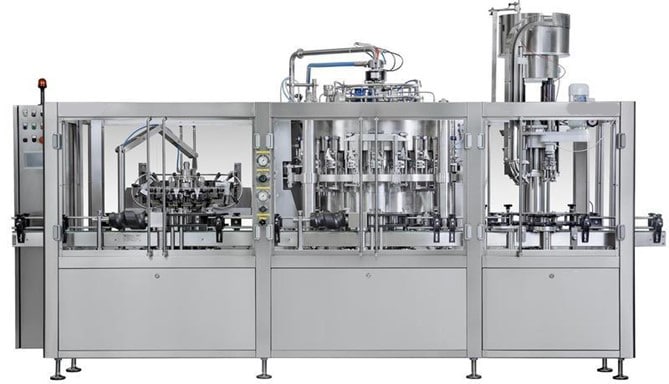

Rinser / Filler / Capper Monoblocks

IC Filling Systems can supply a wide range of different size Rinser / Filler / Capper Monoblocks, small, medium and large, all tailor-made to cater for your rinsing, filling and capping requirements for a range of liquid products.

For any need you may have, we have a solution to offer you.

Our range of products is extremely wide. It includes automatic and semi-automatic machines for every type of rinsing, filling and capping of glass or PET bottles. We also cater for aluminium cans & bottles, for carbonated or non-carbonated liquids. Throughputs range from 500 to 16,000 bph.

We can offer free standing bottle rinsers. Free-standing fillers. Free-standing cappers. We can offer a virtually infinite number of configuration combinations between rinser, filler and capper. We manufacture every machine according to the specific requirements of the customer.

Ask one of our sales team & we will offer you the best solution for your needs.

Checking...

Retry »

Sending message...

Send us your enquiry today...

Tell us what you need, and we'll respond promptly.

For detailed information

Contact our Sales Director Marco Solferini by calling

+39 0141 162 0091 or +39 0141 74166 (Italy)

+44 1865 520 083 (UK)

Alternatively request

a quotation

Can’t find what you’re looking for?

Search this site...